In a small town called Wooburn Green, a group of eleven people came together in the Wooburn Craft School from the 14th until the 17th of February 2023. Despite the fact that they spoke different languages, there was one thing that united them: their desire to learn about leather restoration. But before the leather workshop even started, there was a hurdle to overcome. Theo Sturge, the leather conservator and professor for that week, had caught Covid. But like leather, Mr. Sturge was strong, and together with the appropriate measures, and more importantly, his assistant Ernest Riall, who runs the Craft School, they made the week a success.

After a small introduction of the participants, the workshop started off with an assignment. The assignment was to iron leather that was completely wet. Little did we know, we were trapped. This method taught us the most important lesson of leather restoration: never use heat and water on leather at the same time. I will never forget. Each morning started with a cup of tea and a treat, followed by theory that would introduce the practical for that afternoon. The theory was accompanied by many case studies from Theo’s working experience. Several subjects were covered; ranging from cleaning of leather, to preparing filling materials and filling leather, to retouching and dying leather. The group seemed to have a preference for gilt leather. Therefore, the course content was slightly shifted towards gilt leather restoration.

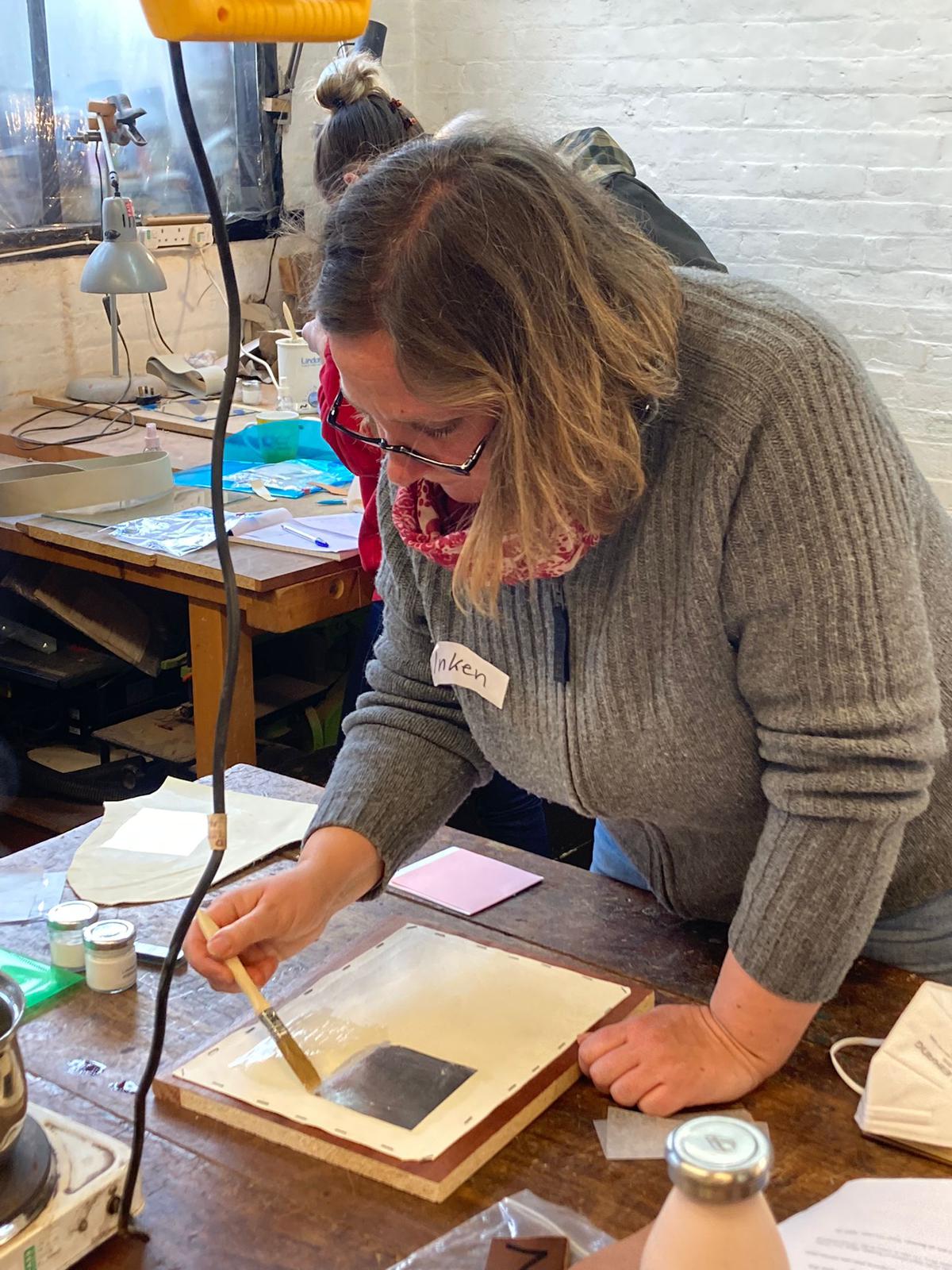

Next up in the workshop was to create our own gilt leather. Because, in order to understand gilt leather, it is important to understand the production process. Therefore, on the first day we applied silver leaf to a piece of leather. The silvered leather was then manipulated by means of a mould. We had the choice to use a mould depicting a beautifully curved (and carved) dragon, or a bird designed by Mrs. Sturge.

After the leather had dried, we applied a layer of varnish to give it its golden appearance. Theo also taught us how to identify different types of animal leather and the difficulty of this identification. The same day we made some preparations for filling materials. For instance, BEVA 371 was coloured with pigments and left to dry for the night. The subject of feathering the edges for leather patches was also covered.

During the following two days we performed several adhesive tests with different adhesives and different materials. We experienced their advantages and disadvantages for adhering to leather. The results from these tests were put to practice during the process of filling leather pieces with BEVA, Reemay (polyester non-woven), leather and other materials that were introduced during this workshop. The fillings were matched as close as possible to the original leather by means of creating relief, dying the leather and by retouching with dyes and acrylics.

All in all, personally I learned that leather is a peculiar material that is as much alive as it is dead. It requires knowledge for a proper restoration and in order to continue to live on. Many thanks for the blood (especially from the saddle stitch), sweat and fortunately only tears of happiness that were put into this workshop by the participants, and first and foremost, Theo Sturge and Ernest Riall.

Daniëlle Stobbe MSc is an APP1 student at the University of Amsterdam

Useful links: