Life in plastic: repairing architectural plans on polyester film

Project background

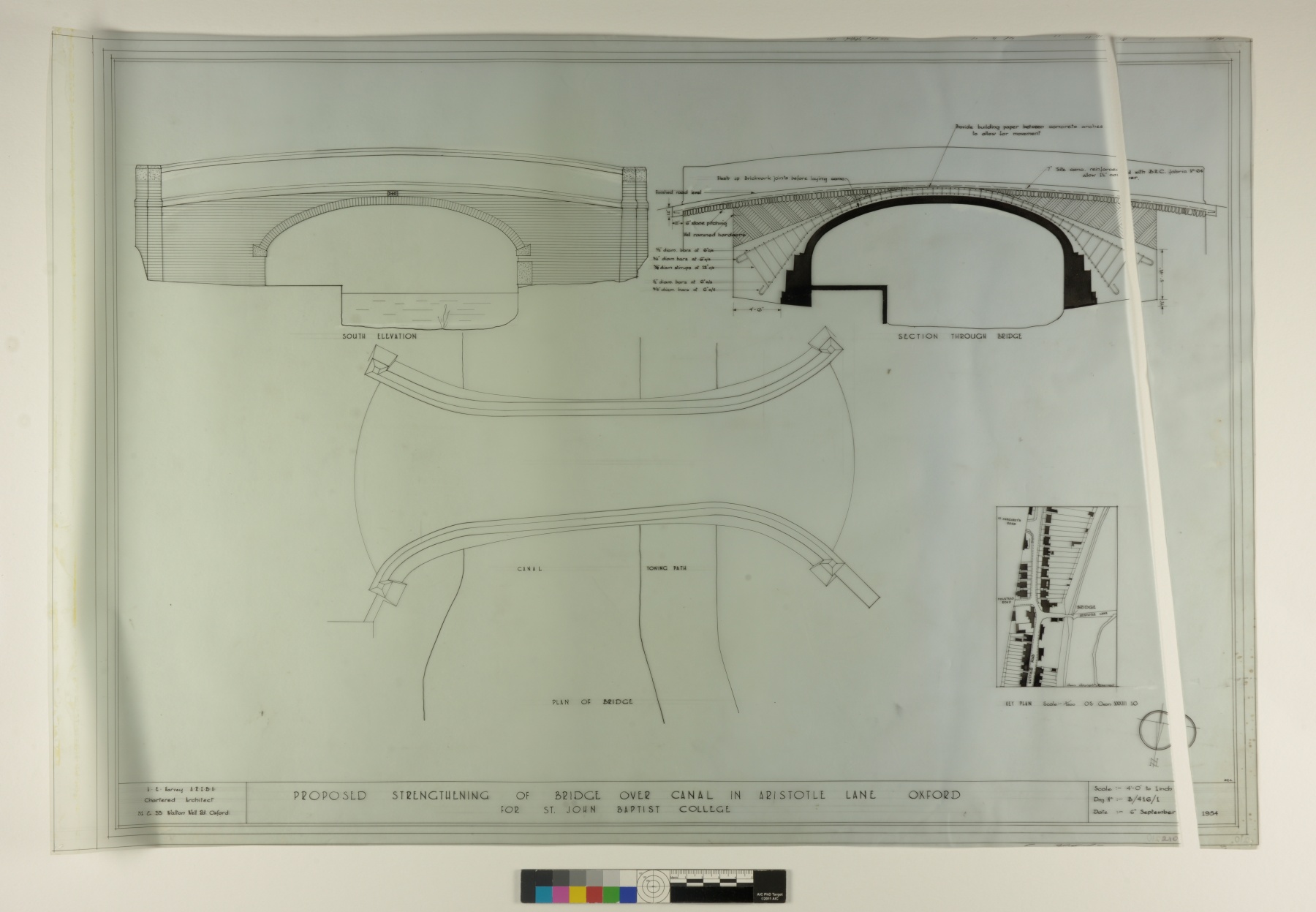

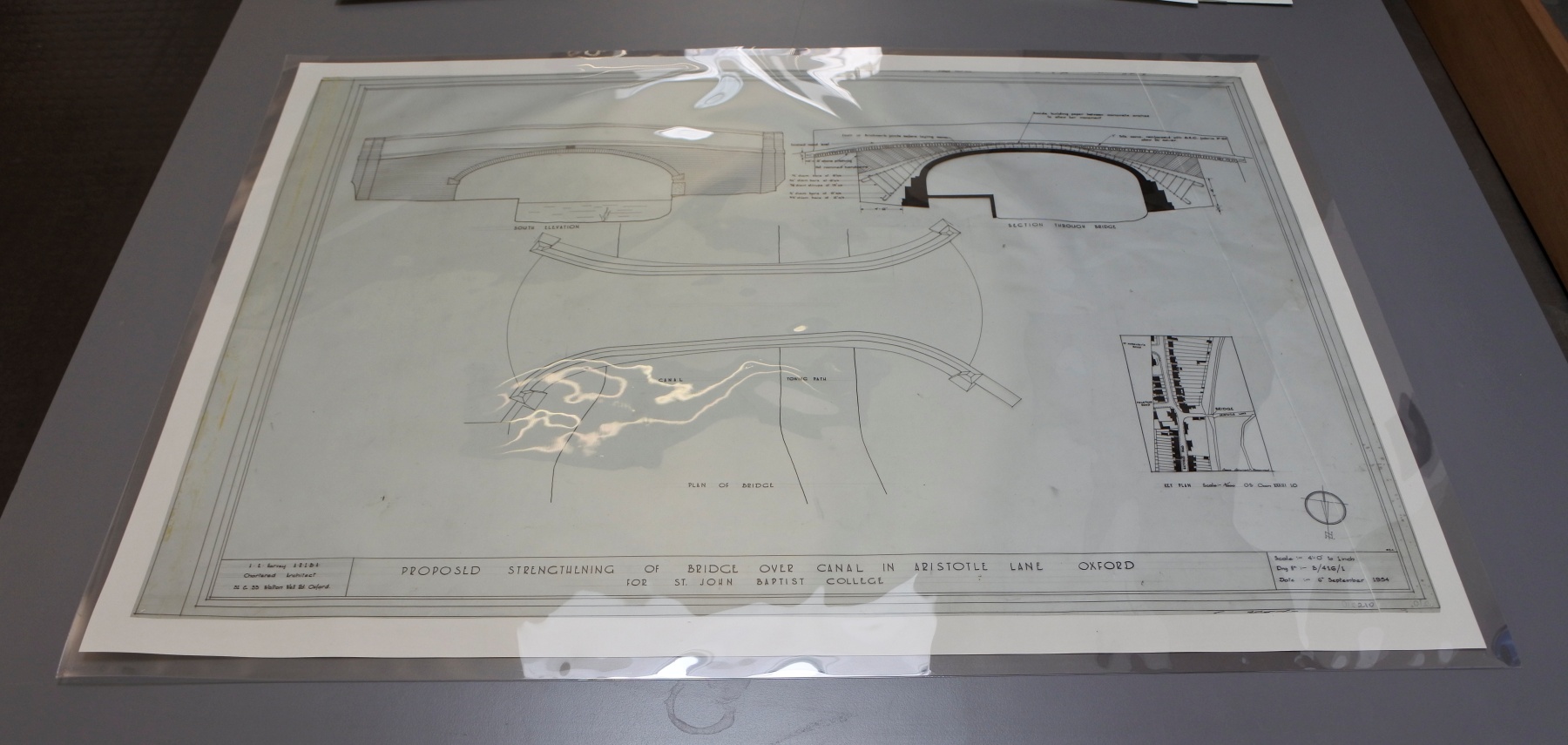

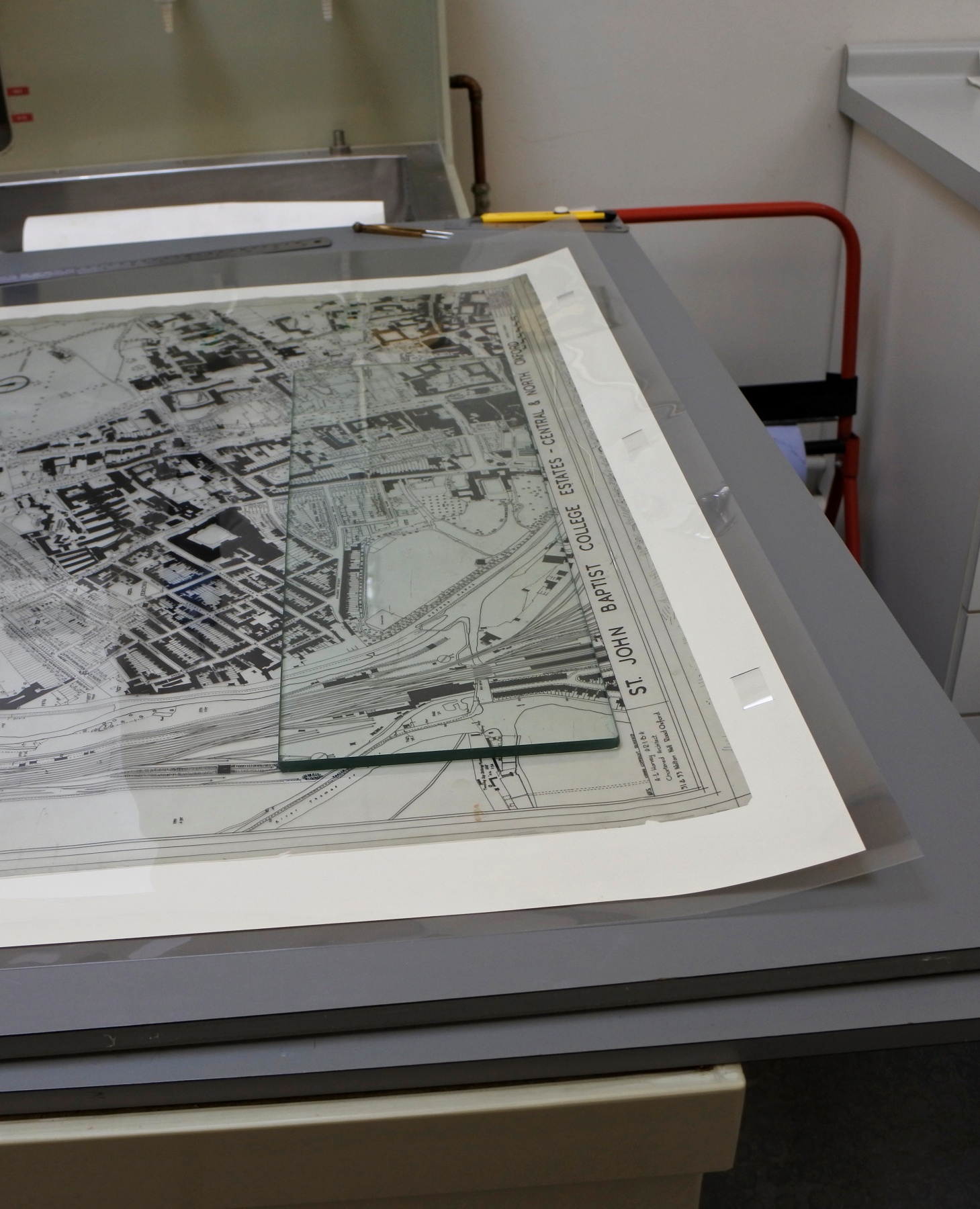

In 2019, St John’s College Archive received a collection of maps and plans pertaining to college-owned properties managed for the college by their agents, Savills. The agency was going digital, and so the hard copies of the plans were deposited with the college archive. The material ranged from huge cloth-backed maps to 1950s plans on plastic drafting film. When the Oxford Conservation Consortium was tasked with treating this new intake of material, the plans on plastic film presented a particular conundrum. As book and paper conservators, we are used to working with paper, parchment, leather, and even wood, but plastic was new to us. Treating the plastic plans therefore provided an intriguing challenge as well as an exciting opportunity to learn more about how to conserve this modern material.

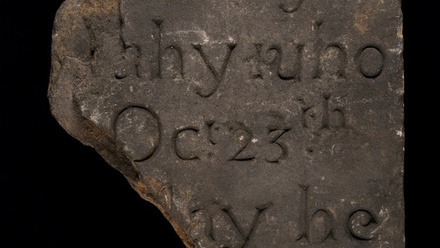

There were 7 plastic plans in total, which were either bluish or yellowish in colour. Most had been stored hanging from cardboard hangers, adhered along one edge, and were in good condition. However, one had been sharply folded and had shorn all along the length of the fold, leaving a large fragment detached. A second had some small shear tears along the top edge, along with a couple of fragments detached due to brittleness along that edge. Another, very large, plan (685mm x 1095mm) had been stored tightly rolled and its outer edge was extensively damaged, with large tears and some losses. Smaller tears were evident on its upper and lower edges where the tight rolling had caused it to shear. All of the plans gave off a pungent chemical smell.

My colleague Nikki Tomkins and I were tasked with treating the plans. Our aim was to safely rehouse the plans in order to make them accessible to researchers, while ensuring that existing damage did not worsen nor further damage occur during future handling. We also wanted to prevent fragments becoming separated and lost. In order to formulate a suitable treatment proposal, we needed first to establish what kind of plastic we were dealing with. We were particularly concerned about the implications of the smell rising from the plans—whether it was toxic either to us and/or future users and/or damaging to the other material stored alongside the plastic plans. As a precaution, we removed the plastic plans from the other material and stored them in a separate folder until we knew more.

Research and identification of materials

Luckily, the Consortium is fortunate to have the Chantry Library housed in our building, and so I first turned to the literature to seek out information on the history of architectural plans on plastic film. From the available books and articles, I discovered that our plans were likely to be made of polyester (or, to be more accurate, the polyester resin polyethylene terephthalate a.k.a PET) with a matte coating on the printed side to receive the ink. This theory was supported by a number of other conservators with whom I corresponded about the material, though it was also noted that the 1950s would be quite early for polyester to be used.

While we were fairly certain that the plans were made of polyester—and would thus be relatively stable and non-toxic—there was a chance that they could be made of either PVC or cellulose acetate, both of which are much less stable materials. Cellulose acetate gives off acetic acid as it deteriorates, producing a ‘vinegary’ smell, while deteriorating PVC smells of chlorine. We were concerned that the smell we had noticed might be a result of this off-gassing, though it did not immediately smell of vinegar or chlorine to us.

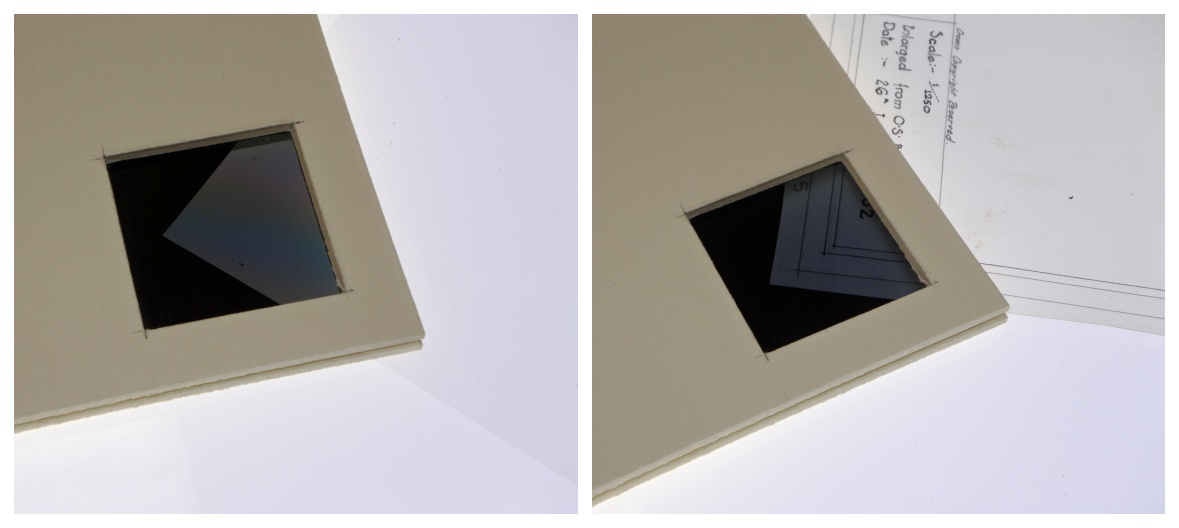

In order to rule out the possibility that the plans were made of cellulose acetate, we constructed a polarising viewfinder following the instructions available here. The test relies upon the fact that, when viewed through polarizing film, polyester produces a rainbow-like birefringence whereas cellulose acetate (or nitrate) does not. Additionally, polyester would appear brighter and clearer through the film whereas cellulose acetate would appear dark. Happily, we found that the plastic plans in our care—while not exhibiting obvious birefringence, perhaps due to the matte coating on the recto of the plans—appeared bright and clear through the viewer and so could not be cellulose acetate.

We were less certain about how to rule out PVC as a possibility for the support material, as we were unable to find out whether PVC would also appear bright and clear through the viewfinder. But as you will see, more evidence came to light later to confirm our suspicions that the film was made of polyester.

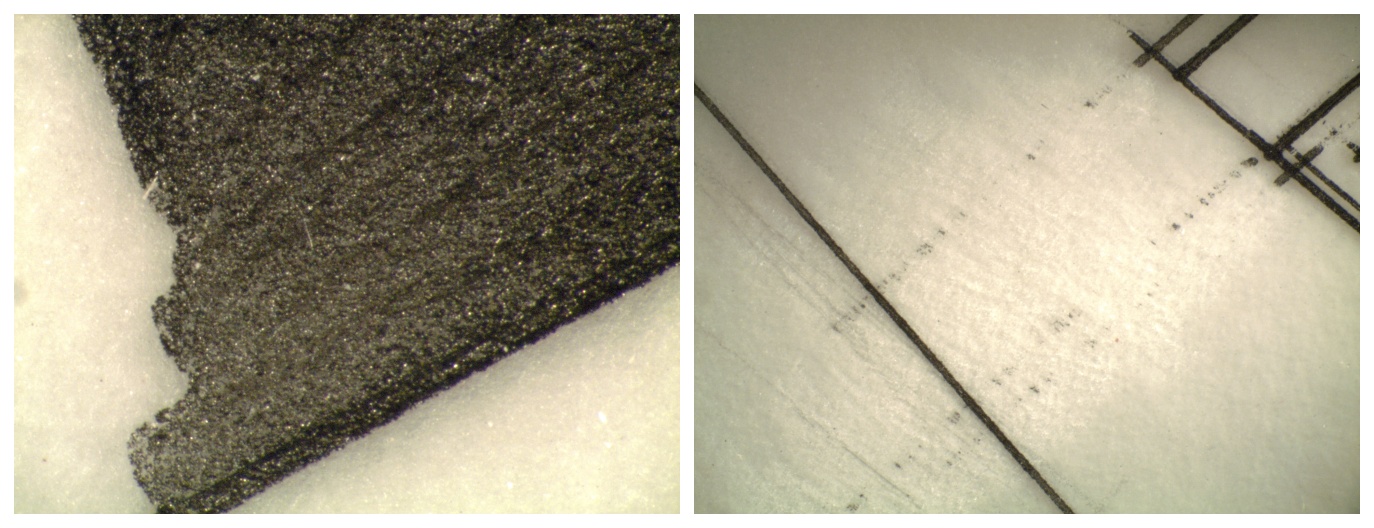

We then turned to the question of what type of reproductive process (if any) had been used. This took a lot of detective work! Based on the date of the plans and the plastic film support, we narrowed it down to three possibilities: diazotype, wash-off print, or else simply hand-drawn. At first, we thought that the diazotype process was most likely given the smell we had detected. Diazotypes are developed using ammonia vapours and are often identifiable by a strong residual odour. However, upon examining the plans under a microscope, we found they did not demonstrate other features one would expect to see from a diazotype. Namely, the ground was not smudged or flecked, and the lines were sharply delineated as opposed to the fuzzy edge one would expect to see on a diazotype. The lines on our plans were also a vivid, ink-like black, which would not be the case with a diazotype.

Given the nature of the lines, we considered wash-off prints. Wash-off prints have dark black, ink-like lines, sometimes with a slightly metallic sheen, that sit high upon the support surface and contrast starkly with a smooth, clean ground. On wash-off prints, lines could be corrected or modified directly on the support, so there may be hand-drawn alterations present. This seemed more similar to what we could see on our plans. However, we still had some doubts that they were wash-off prints. According to the literature, wash-off prints were often printed in reverse, meaning that you had to read them through the verso of the print with transmitted light, which was not the case with ours. The literature also described amendments to wash-off prints being carried out with erasers or ‘liquid eradicators’. Though one of our plans showed signs of being modified, under the microscope it was clear the original lines had been scraped away with a blade.

In the end, we decided it was most probable that the plans were entirely hand-drawn. There was black ink, graphite, and ballpoint pen present and all seemed to sit on the surface of the film in the same way, as opposed to some being printed and others being later additions. Under the microscope, blocked-out areas of black showed the individual pen strokes, while the graphite lines had a different light reflectance and hue, suggesting that they really were graphite rather than a reproduction.

Our theory that the plans were hand-drawn on polyester was further backed up by a telephone conversation with Jack Kahn, Managing Director of DEP Ltd, whose family company has been supplying the printing industry since its establishment by Samuel Kahn in 1908. Initially, Mr. Kahn told me that the plans were unlikely to be polyester if they were from the 1950s, as this was only in wide usage from the 1960s onward. In the 1950s, they were more likely to be PVC. However, when I described the smell arising from the plans, he informed me that it probably wasn’t coming from the support at all, but instead from the ink. This ink is specially formulated for use on polyester drafting film, as it etches into the matte coating, and has a very pungent smell. By contrast, the solvent ink used on PVC films—which are calendared rather than coated—smells sweet. The pungent smell coming off the plans is therefore further evidence that they are a) hand-drawn and b) made of polyester.

However, despite this conclusion, we were still aware that we could be mistaken. It is particularly easy to mistake wash-off prints for hand-drawn originals, especially if there are modifications and additions present as well. Hand-drawn additions to an already printed plan could also explain the smell of the ink arising from the items. For this reason, we decided to treat and store the plans as though they may be diazotypes or wash-off prints, just in case.

Treatment and rehousing

The next question was how to repair the plans and make them easier and safer to handle. For this, I turned to the global conservation community, posting my question on the Global Conservation Forum and receiving a great number of helpful responses for which I remain extremely grateful. Other conservators had achieved success in repairing plastic supports using heat-activated tissues prepared with acrylic polymer adhesives. Several people mentioned using a mixture of Lascaux 498HV and Lascaux 303HV adhesive, so this is what we decided to try.

We made a number of different coated tissues in order to determine the most suitable ratio of Lascaux 498HV to Lascaux 303HV for our purposes, and also the most suitable dilution of adhesive to water. Lascaux 303HV is more flexible than the 498HV and remains very tacky at room temperature. 498HV forms a slightly less flexible film and is less tacky at room temperature. We tested out our tissues by adhering them to pieces of new polyester film, which we cut with scissors to simulate the tears in the plans. In the end, we decided on a 50/50 mix of the two adhesives, diluted 1:4 in deionised water.

Curiously, we discovered that we did not need heat to ‘reactivate’ the tissue: it was tacky enough to stick firmly to the polyester with merely the pressure of a Teflon folder. Manipulating the repair revealed that it had very good tensile and folding strength, but that it could be peeled off without leaving any visible residue. Using a heated spatula to put down the repair did not appear to make any difference to its strength.

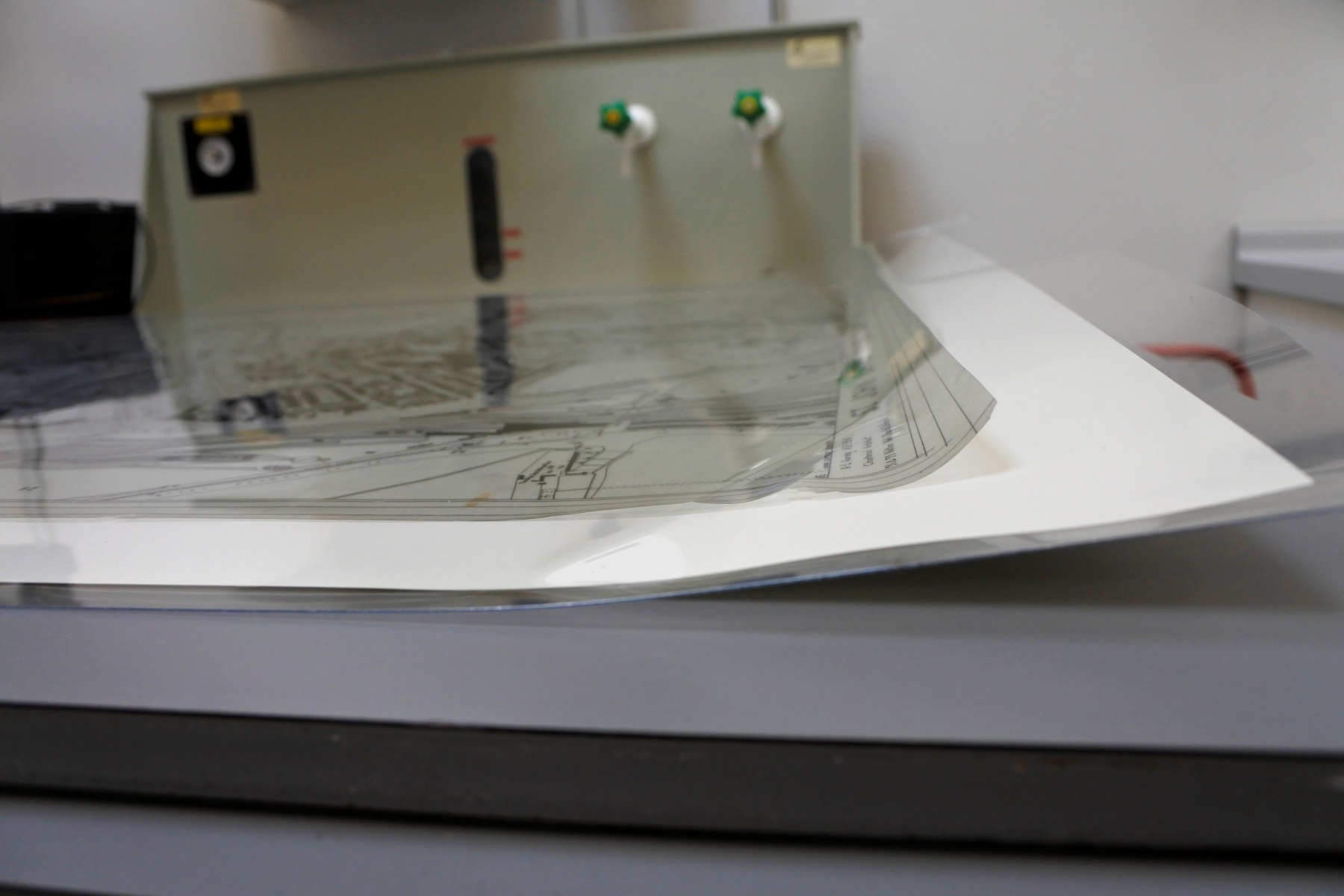

The repairs were, however, very opaque in comparison to the transparent polyester we used as our test samples. While the plans we were to repair were translucent rather than transparent, we realised that our repairs would remain quite visible. To mitigate the aesthetic disturbance and any disruption of the design elements, we decided to apply very small splint repairs, bridging the tears at intervals. We also thought these would be in less danger of peeling away during handling, in comparison to larger ‘strip’ repairs running all the way along the tears.

While the permanent ‘tack’ of our repairs was useful for the ease of application, we were concerned about them dislodging and potentially sticking to adjoining items in the future. To avoid this, and also to add an extra layer of protection to the vulnerable plastic, we decided to house the repaired plans in individual polyester sleeves. A backing layer of unbuffered Argentia paper was laid beneath the repaired plans and then both were inserted into a polyester sleeve. Unbuffered paper was chosen over buffered as a precaution in case we had wrongly identified the plans, as diazotype prints can be alkaline-sensitive. The two smaller plans could then be stored flat in a folder alongside the other plastic plans that had not required repair.

The tightly rolled format of the larger plan had been the cause of many of its tears, so we also wished to store this flat. Luckily, St John’s Archive has a plan chest just big enough to accommodate its size. We purchased some extra-large polyester sleeves in order to fit the plan inside, again with a backing of Argentia. However, once within the polyester sleeve we found that the plan was still tending to curl up at one end, pushing the sleeve open. Luckily, we had left a wide margin at the open end which allowed us to come up with a solution. We cut regular slits in the sleeve and the paper backing at the open end and slotted through strips of polyester to hold the sleeve closed. The ends of the strips were then tucked back through slots in the polyester sleeve so that they lay between the lower layer of the sleeve and the paper, ensuring that they would not get caught on anything during handling.

The treatment of the plastic plans was an overall success, with the damaged items now much safer and easier to handle—though we will be keeping an eye on the long-term performance of our Lascaux repairs. The research we conducted while treating the items has been particularly eye-opening, highlighting the value both of liaising with fellow conservators and reaching outside of the conservation sphere for industry-specific knowledge on modern materials. We would particularly like to find out more about the composition of the drafting ink that gives off such a pungent smell, and what precisely is being off-gassed. In the meantime, we are recommending handling the plans in a well ventilated space, consulting only one at a time to reduce exposure to the smell, and ensuring they are stored separately to other materials.

Jess Hyslop is a book and paper conservator at the Oxford Conservation Consortium. Jess completed her MA at West Dean College in 2016. She was a project conservator for one year at the Staffordshire and Stoke-on-Trent Archive Service prior to joining the OCC in 2017.

Key references

- Chantry Library

- Lois Olcott Price, Line, Shade and Shadow: The Fabrication and Preservation of Architectural Drawings (Oak Knoll Oress, 2015)

- Eléanore Kissel and Erin Vigneau, Archtectural Reprodutions: A Manual for Identification and Care (Oak Knoll Press, 1999)

- Preservation Self-Assessment Program at University of Illinois Libraries, Architectural Drawing Reproduction (accessed 29 April 2021)

Acknowledgments

Our thanks go out to all those who advised us during the research and treatment process, including (but not limited to!):

- Michael Riordan, Archivist, St. John’s College

- Jane Eagan, Head Conservator, Oxford Conservation Consortium

- Celia Bockmuehl, Senior Conservator, Oxford Conservation Consortium

- Karen Potje, Head of Conservation and Preservation, Canadian Centre for Architecture

- Marion Cinqualbre, Independent Conservator

- Victoria Stevens, Independent Conservator

- Laura Hashimoto, Conservator, Libraries and Archives Canada

- Robin Gibson, Independent Conservator

- Jack Kahn, Managing Director, DEP Ltd.